Service

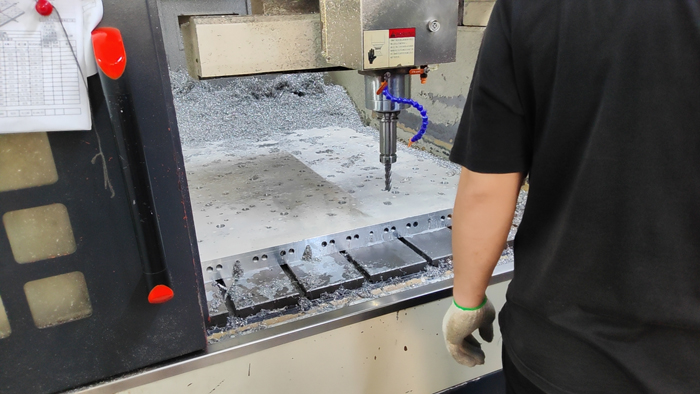

CNC machining service

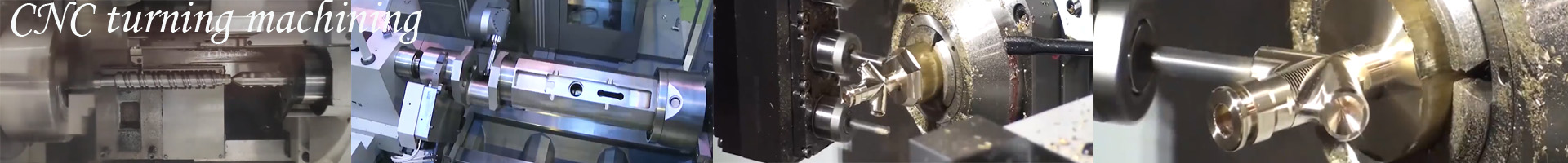

Jinc’s CNC machining services offer you precision fabrication of metal parts in any volume. We specialize in multi-axis CNC milling, CNC turning, surface grinding, laser engraving and much more.

CNC Machining – What Is It and Why Do You Need It?

The CNC machine tool automatically processes the parts to be processed according to the pre-programmed processing program. We put the machining process route of the part, process parameters, tool motion trajectory, displacement, cutting parameters (spindle revolutions, feed, back-feeding amount, etc.) and auxiliary functions (tool change, spindle forward rotation, reverse rotation, The cutting fluid is turned on and off, etc.), according to the instruction code and program format specified by the CNC machine tool to write a processing program list, and then record the content of the program list on the control medium (such as perforated paper tape, magnetic tape, magnetic disk, magnetic bubble memory), and then input into the numerical control device of the numerical control machine tool, thereby directing the machine tool to process the parts.

CNC machining is used on many common metals such as aluminum, brass, mild and stainless steels, and titanium.

Because of the reliability and precision afforded by modern tools controlled with sophisticated software, CNC machining is an ideal rapid prototyping and production volume solution for making complex end-use parts with very tight tolerances.

One of the great advantages to CNC machining is its versatility. It is highly flexible and adaptable to many shapes and sizes of parts, and because there is no need for fixed tooling one part can be made just as easily as one thousand. CNC machined components are full strength and they have excellent surface finishes. You can choose to put them into service immediately or they can be further processed with additional treatments such as plating, polishing, anodizing, painting and more.

Advantages Of CNC Machining Services

1.Flexible machining capability

2.Highly accurate and repeatable

3.High processing productivity

4.Reduce operator labor

5.Excellent for making complex geometries

6.Stable processing quality

Our Advantages of CNC Machining

1.Rich experience on CNC machining area

2.Fast turnaround

3.Advanced Equipment

4.Excellent surface finishes

5.Easily customized

CNC Machining Raw Materials

We work with a wide range of plastic and metal alloy materials including mild and stainless steel, aluminum, brass and titanium as well as rigid engineering grade plastic resins. These materials are part of our standard inventory and can be sourced for immediate availability from reliable vendors who have been thoroughly vetted and approved by us. In addition we can also provide specialty materials such as super hard alloys – just talk with our engineers to learn how we can meet your needs.

Capacity

|

Items |

Size Max. |

Tolerance |

|

CNC Milling machines |

1600 * 1200mm |

±0.01mm |

|

CNC Turning machines |

ø0.5~ø350mm length:1000mm |

±0.005mm |

Material available

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, AL1060,AL2024,A380 etc. |

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316,SS430 etc. |

|

Steel |

SPCC Cold Rolled Steel,mild steel, Carbon steel, 4140, 4340, Q235(A3), Q345B, 20#, 45#,40Cr,65M..etc. |

|

Titanium alloy |

TA1、TA2、TA3、TA4、TA5、TC4、TC6、TC11,pure titanium |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

T2,T3,(110 1/2 hard) C11000,C12000,C12000 C36000 etc |

|

Bronze |

phosphor bronze,aluminium bronze,tin bronze,silicon bronze,beryllium bronze |

|

Plastic |

ABS,PC,PA,PP,PMMA,POM,PA+GF30,PPA+GF30,PPA,PEEK,PEI,bakelite...etc. |

|

Invar |

Invar36, 1.3912 |

|

Iron |

12L14,1213,1215 ...etc |

Surface Finish

Aluminum |

Stainless Steel |

Steel |

Titanium alloy |

Brass |

Copper |

Bronze |

Plastic |

|

Sandblasting |

Polishing |

Polished,Brushing,Sandblasting |

Sandblasting |

Sandblasting |

Sandblasting |

Sandblasting |

Sandblasting |

|

Brushing |

Passivating |

Zinc plating |

Brushing |

Brushing |

Brushing |

Brushing |

Brushing |

|

Polishing |

Sandblasting |

Blacking(black coating) |

Polishing |

Polishing |

Polishing |

Polishing |

Polishing |

|

Normal Anodized(3~15μm) |

PVD coating |

Nitriding |

Anodizing |

Nickel plating |

Nickel plating |

Nickel plating |

Painting |

|

Hard Anodized(15~30μm) |

Painting |

Nickel/Tin plating |

Nickel plating |

Tin plating |

Tin plating |

Tin plating |

Silkscreem painting |

|

Hard Anodized(30~55μm) |

laser engraving logo/letters |

Chrome plating |

electroless plating |

laser engraving logo/letters |

laser engraving logo/letters |

laser engraving logo/letters |

laser engraving logo/letters |

|

Chemical Film |

|

Heat treatment |

|

|

|

|

|

|

Chrome plating |

|

|

|

|

|

|

|

|

PVD Coating |

|

|

|

|

|

|

|

|

Painting |

|

laser engraving logo/letters |

|

|

|

|

|

|

laser engraving logo/letters |

|

|

|

|

|

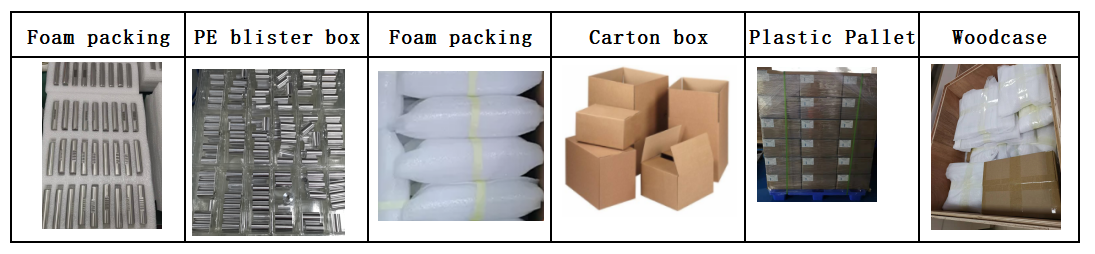

Packaging

Application for Aerospace parts,Automotive parts,Mechanical parts,Electronic parts,Military parts,5G device,Drone parts,Medical parts,instrument equipment.sports equipment,...etc.

Application for Aerospace parts,Automotive parts,Mechanical parts,Electronic parts,Military parts,5G device,Drone parts,Medical parts,instrument equipment.sports equipment,...etc.

Service

Contact Us

Name: Sales Team

Mobile: 158 2047 0409

E-mail: [email protected]

WeChat: 158 2047 0409

Whatsapp: +86-158 2047 0409

Add: No. 2, Xinwei 1st Road, Sha'jiao, Humen Town, Dongguan City, Guangdong,China

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry